Manufacturing

End Grain Cutting Board.

As a holiday gift for my mother, I designed a 12x12x1.25 inch cutting board using four different types of hardwoods: Padauk, Purpleheart, African Mahogany, and Cherry. This project proved challenging due to the interconnectedness of the different woods. Even though all the pieces were cut at the same angle, there ended up being a 4° gap between pieces at the final glue up. To solve this problem, I incorporated traditional machining methods using a mill to get the tight tolerances needed for a seamless fit!

Collaborators:

Skills Used:

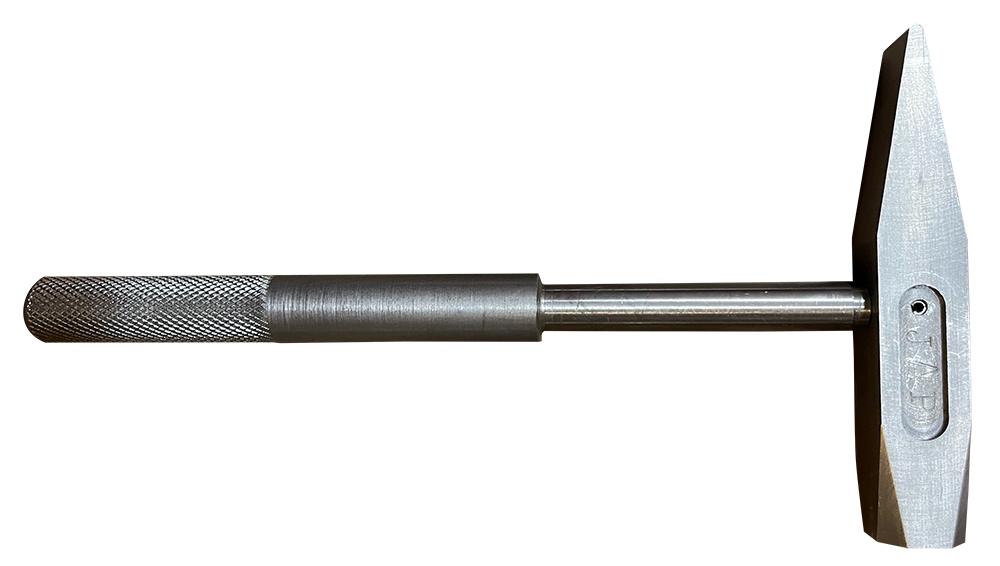

Decorative Hammer.

I manufactured a decorative hammer to level up as a shop trainer in the engineering design studio at Northwestern. The hammer was manufactured as two separate parts: the handle and the head. Each part of the hammer was graded within strict measurement tolerances. I knurled the handle after for decoration.

Skills Used:

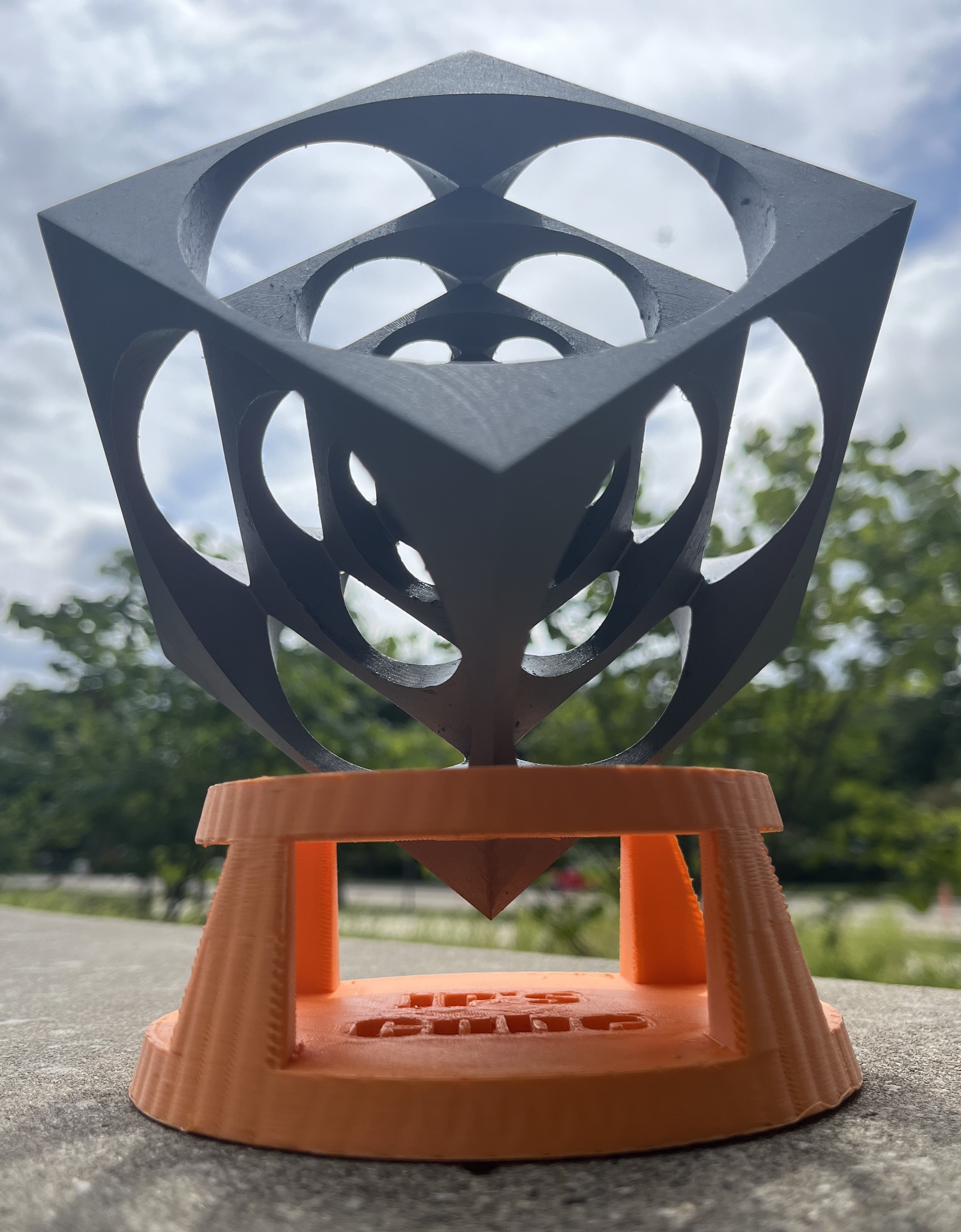

Turner's Cube.

While I am no expert, I am learning how to program different CNCs! I have been learning to use CNC's including the Mill and Lathe. Here is my first project I manufactured on the CNC mill!