X-Ray Positioning Device

Collaborators:

Introduction:

Of all the projects I have worked on, this project is my favorite. As a freshman in the Northwestern McCormick school of Engineering, we are required to take 2 quarters of design thinking communication (DTC) classes. During my first quarter of this class, my team was contracted to help a mother with an incapacitated son. The son, as the mother put it, was hit by the "perfect storm," and lost all motor and verbal capabilities.

Problem:

Our client frequently needed to bring her son to receive lung x-rays to ensure his lungs weren't filling up with fluid. However, this process required that the mother support the entire weight of her son from the front, as a nurse supported his head, while an x-ray film was placed on one side of his body and the x-ray camera took an image from the other. This process was quite strenuous on the mother and will only become more difficult as she ages.

Mission Statement:

Design and prototype a device that supports the user during x-rays and allows for clear imaging.

Design Considerations:

- The X-Ray image must be unobstructed by non-radiolucent materials. Our support must account for this.

- Our design should be as comfortable and as low effort as possible. A design that required our user to switch wheelchairs would cause the same amount of "physical exertion" as the problem.

- Our design must be usable by other patients too. It would be ineffective if it only worked for one user.

- Must be portable.

- Must support the entire of an incapacitated body.

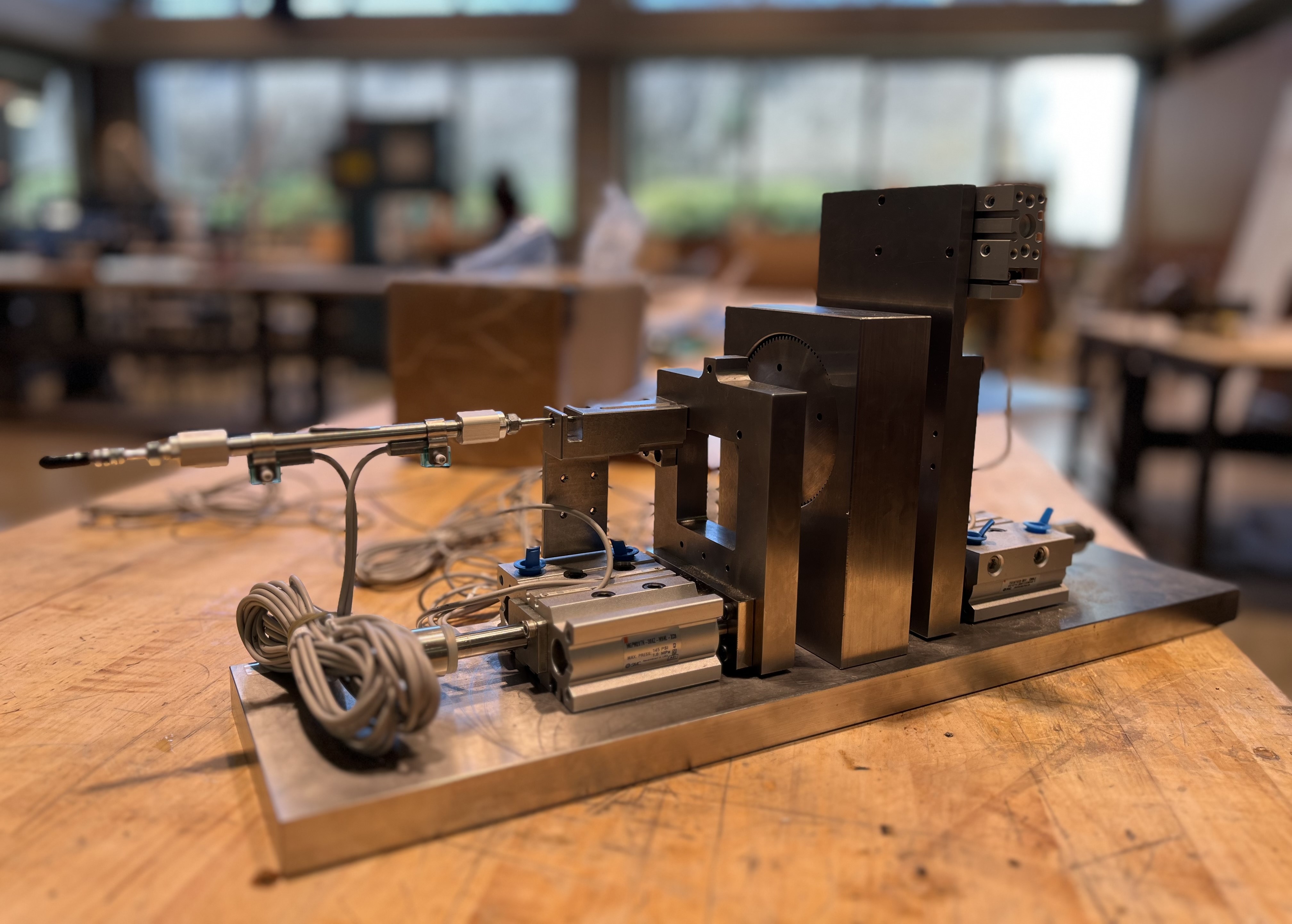

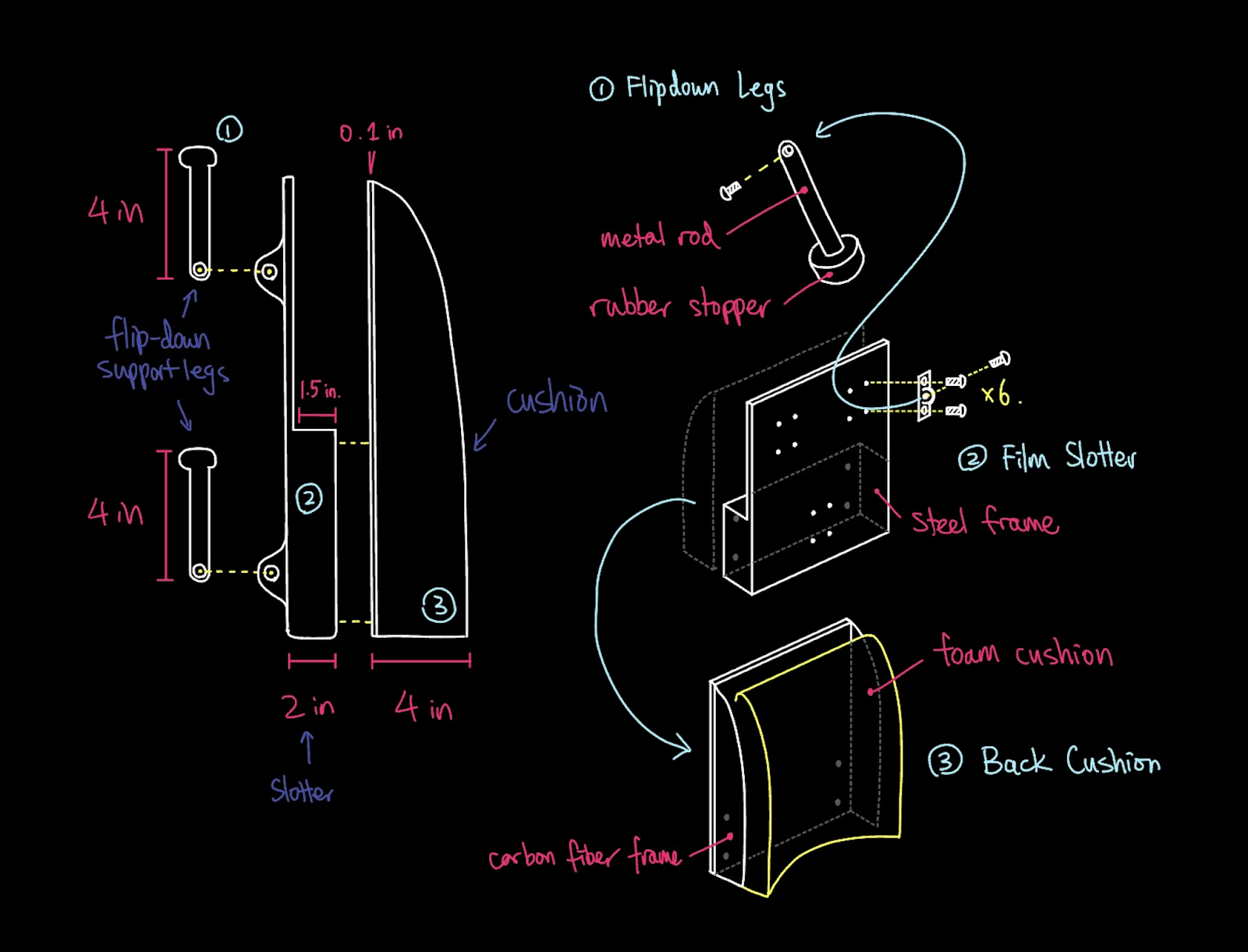

Our solution was to design a device that could support the son's body weight and hold the x-ray film. This would require no interaction from the mother and allow the son to receive his x-rays effortlessly. We designed a back support with a slot for the film from radiolucent shape memory polymer (SMP) foam. This would hold the film while allowing the x-ray beams to pass through Nick and the backing. The device had a rigid support structure made from wood that had an extendable leg support attached to it. This would allow our device to account for different chairs and stay support in all of them.

The wood and backbones to hold the flip down support leg were lasercut. The support leg was made from the bottom part of a recycled crutch that allowed for extendability. The foam was hand-sawed then adhered to the rigid back support with special 3M foam adhesive.